Isicelo: Isetyenziswa kakhulu kwi-brushless motor, imagnethi esisigxina yemoto yeshishini, i-motor ye-textile, i-automobile motor, i-magnet esisigxina ye-drive motor, i-linear motor, i-air conditioning compressor motor, izixhobo zoomatshini ezisisigxina zemagnethi motor, ijenereyitha yaseLwandle, ijenereyitha yemagnethi esisigxina, i-magnetic propulsion motor. , imigodi yemagnethi esisigxina yemoto, i-coupling motor, i-chemical magnetic motor esisigxina, i-motor motor ye-EV, i-motor motor, i-EPS motor, inzwa kunye nenye indawo.

Imveliso eyenziwe ngokwezifiso: umazibuthe zonke zilungelelanisiwe, ubude bunokuba ukusuka ku-0.5mm-200mm, ububanzi ukusuka ku-0.5mm-150mm, ubukhulu busuka ku-0.5mm-70mm, obunokuhlangabezana nemfuno yabathengi abaninzi.

Ukwaleka: Imagnethi yeNdfeB kulula ukuyikhupha, ke ngokwesiqhelo ifuna ukugquma, isambatho esiqhelekileyo esisetyenziswa kwimarike njenge:

1. Ukufakwa kwe-ZN (uhlobo oluthile lwentsimbi, uvavanyo lokutshiza ityuwa lunokufikelela kwiiyure ezingama-24-48, ukusebenza kweendleko eziphezulu, ngoko ke yenye yezona zinto zikhethwa kakhulu kubathengi abaninzi).

2. I-NICUNI (uhlobo lokutyabeka kwesinyithi, uvavanyo lokutshiza ityuwa lunokufikelela kwiiyure ezingama-48-72, ukusebenza kweendleko kuphezulu kune-ZN, kodwa kusetyenziswa kakhulu kwimarike imeko yendibano ibukhali, iimfuno zokuxhathisa imveliso yomthengi unako. khetha).

3. I-Epoxy (i-non-metallic coating, i-non-magnetic conductivity, inokunciphisa ilahleko ye-motor eddy yangoku, uvavanyo lokutshiza ityuwa lunokufikelela kwiiyure ezingama-72-96, ixabiso eliphezulu kune-ZN ye-NICUNI yokwambathisa.)

4. Okunye ukutyabeka okwasetyenziswayo: Phosphate, Sn, Au, Ag, Parylene njalo njalo...

Ukunyamezela: Ngokuqhelekileyo ukunyamezela kwethu kwemagnethi ku +/-0.05mm emva kokugquma.

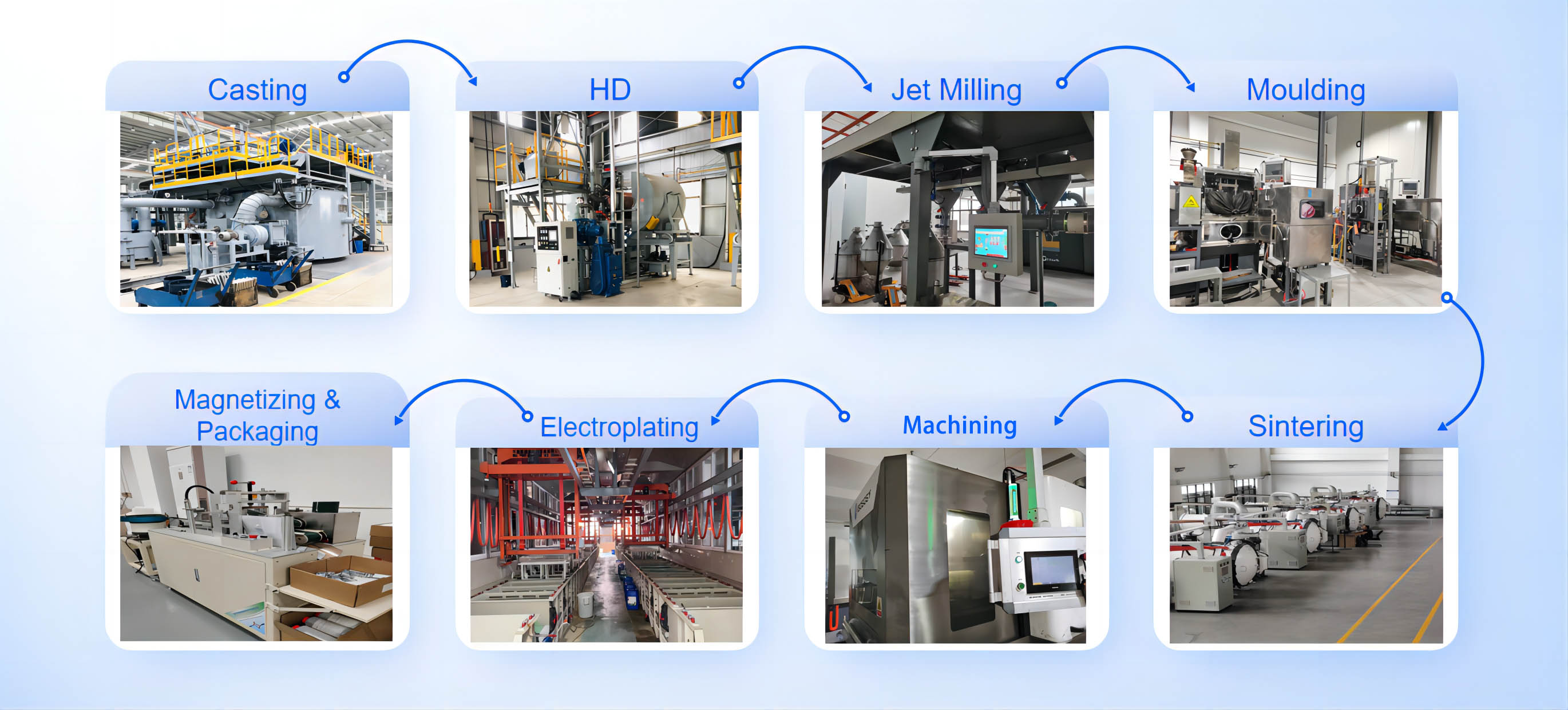

Inkqubo yeMveliso yeNdFeB

Ukwaleka Intshayelelo

| Umphezulu | Ukwaleka | Ukutyeba μm | Umbala | Iiyure ze-SST | Iiyure zePCT | |

| Nickel | Ni | 10~20 | Isilivere eqaqambileyo | >24 ukuya kutsho ku72 | >24 ukuya kutsho ku72 | |

| Ni+Cu+Ni | ||||||

| I-Nickel emnyama | Ni+Cu+Ni | 10~20 | Umnyama Oqaqambileyo | > 48-96 | >48 | |

| Cr3+Zinc | Zn C-Zn | 5 ~8 | UBrighe Blue Umbala Oqaqambileyo | >16 -48 > 36 -72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Isilivere | > 36 -72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Igolide | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Isilivere | >12 | >48 | |

| Epoxy | Epoxy | 10~20 | Mnyama / Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15 ~ 30 | >72 ~108 | --- | |||

| Zn+Epoxy | 15 ~ 25 | >72 ~108 | --- | |||

| Ukunyamezela | --- | 1~3 | Grey emnyama | Ukhuseleko lwexeshana | --- | |

| Iphosphate | --- | 1~3 | Grey emnyama | Ukhuseleko lwexeshana) | --- | |

Iimpawu zoMzimba

| Into | Iiparamitha | Ixabiso leReferensi | Iyunithi |

| I-Magnetic encedisayo Iipropati | I-Coefficient yoBubushushu obubuyiselwayo ye-Br | -0.08--0.12 | %/℃ |

| I-Coefficient yoBubushushu obubuyiselwayo ye-Hcj | -0.42-0.70 | %/℃ | |

| Ubushushu obuthile | 0.502 | KJ ·(Kg ·℃)-1 | |

| Ubushushu beCurie | 310~380 | ℃ | |

| Mechanical Physical Iipropati | Ukuxinana | 7.5~7.80 | g/cm3 |

| Vickers Ukuqina | 650 | Hv | |

| Ukunyangwa koMbane | 1.4x10-6 | μQ · m | |

| Amandla acinezelayo | 1050 | MPa | |

| Tensile strength | 80 | Mpa | |

| Ukugoba Amandla | 290 | Mpa | |

| I-Thermal Conductivity | 6 ukuya ku-8.95 | W/m ·K | |

| Imodulus yolutsha | 160 | GPA | |

| Ukwandiswa kweThermal(C⊥) | -1.5 | 10-6/℃-1 | |

| Ukwandiswa kweThermal(CII) | 6.5 | 10-6/℃-1 |

Umboniso Wemifanekiso

-

Isingeniso kwi-Isotropic kunye ne-Anisotropic Ferrite

-

Abathengisi behoyilesi yeSampuli yasimahla ye-N52 Block Neod...

-

Phonononga ubungakanani obahlukeneyo beeMaginethi zeFerrite ezibotshelelweyo

-

Iimagnethi zeAlNiCo ezikumgangatho ophezulu ziyafumaneka

-

Ukhetho olukhulu lweMagnet yeNeodymium enamandla...

-

Ukusebenzisa uMjikelo we-NdFeb kwi-Electroacoustic