Ngaphandle koko, iimagnethi ze-SmCo zinezinye iimpawu:

Ukusebenza okuthembekileyo: Iimagnethi ze-SmCo zixhathisa kakhulu kwi-demagnetization zibenza zithembeke kwiindawo ezininzi.

Ukungatya kunye nokumelana ne-oxidation: Ngenxa yomxholo wentsimbi ephantsi kwizinto ezihlanganisiweyo, iimagnethi ze-SmCo zinokumelana okugqwesileyo kokutya.Ngokungafaniyo ne-NdFeB, imagnethi ye-SmCo ayifuni i-electroplating.

Uzinzo lobushushu: SmCo unako ukugcina amandla ayo magnetic kumaqondo obushushu aphezulu (249-300 ℃) kunye namaqondo aphantsi kakhulu (-232 ℃).

Izinto ezinqabileyo: Xa i-sintering, izinto eziphathekayo zinokuba brittle, ngenxa yokuba i-brittle kwaye kulula ukuyiqhekeza, ukucubungula kunemida, apho iindlela zokucubungula zendabuko zingasebenzi.Nangona kunjalo, inokucolwa, kodwa kuphela ukuba kusetyenziswe isixa esikhulu sesipholisi.Kungenxa yokuba into epholileyo inokunciphisa umngcipheko womlilo ukusuka ekuqhekekeni kwe-thermal kunye nothuli lokusila oluxutywe nge-oxidized.

Usetyenziso:

1. Iinjini ze-PM eziphezulu.Iinjini ze-PM ngokubanzi zihlala zisebenzisa iimagnethi ze-ferrite okanye imagnethi ye-NdFeB.Kodwa kwiindawo apho ubushushu budlula i-200 ℃ okanye i-torque enkulu, kuphela ii-motor SmCo PM ezinobuchule.

2. Izixhobo ze-Electroacoustic kwiinkqubo zesandisi-lizwi eziphezulu.

3. Inkqubo yesixhobo ethembekileyo kakhulu.Izixhobo ezininzi ezisetyenziswa kwi-aerospace, i-aviation, ezonyango kunye nezinye iindawo kufuneka zisebenzise iimagnethi ezisisigxina ze-SmCo ukuqinisekisa ukuthembeka okuphezulu kunye nokhuseleko olugqibeleleyo.

4. Kwi-radar ebaluleke kakhulu kunye neenkqubo zonxibelelwano, inani elikhulu leetyhubhu ezihambayo ezihambayo, iimagnetron, iityhubhu ezileqayo, ukuleqa iityhubhu zamaza, iigyrotrons kunye nezinye izixhobo zokufunxa zombane zisetyenziswa, kunye neemagnethi ze-SmCo zenza imiqadi ye-electron ecaleni kwendlela emiselweyo.

5. I-SmCo extractors magnetic kumaqula anzulu angaphantsi kwe-3000 yeemitha, kunye ne-SmCo magnetic drive (ipompo) kwindawo yobushushu obuphezulu obungama-200 ℃.

6. Intloko yokufunxa imagnethi, isahluli samagnetic, i-magnetic bearing, i-NMR, njl.

SmCo Magnet Grade List

| Izinto eziphathekayo | No | Br | Hcb | Hcj | (BH)ubuninzi | TC | TW | (Br) | Hcj | ||||

| T | |KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | %℃ | %℃ | ||

| 1:5 SmCo5 (Smpr)Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| 1:5 SmCo5 | YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | ≥ 1830 | ≥ 23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | ≥ 1830 | ≥ 23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | ≥ 1830 | ≥ 23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | ≥ 1830 | ≥ 23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥ 1830 | ≥ 23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1:5 (SmGd)Co5 | I-LTc(YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | ≥ 1830 | ≥ 23 | 75-8A | 9.5-11 | 750 | 300 | 20-100℃ +0.0156%℃ 100-200℃ +0.0087%℃ 200-300℃ +0.0007%℃ | |

| Ce(CoFeCu)5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990 | ≥ 25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990 | ≥ 25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990 | ≥ 25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990 | ≥ 25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990 | ≥ 25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | ≥ 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | ≥ 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmEr)2(CoTM)17 | I-LTC (YXG-22) | 0.94-0,98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25℃ +0.005%℃ 20-100℃ -0.008%℃ 100-200℃ -0.008%℃ 200-300℃ -0.011%℃ | |

| Iimpawu ezibonakalayo zeSamarium Cobalt | ||

| Ipharamitha | ISmCo 1:5 | ISmCo 2:17 |

| Ubushushu beCurie(℃) | 750 | 800 |

| Obona bushushu bokusebenza (℃ | 250 | 300 |

| Hv(MPa) | 450-500 | 550-600 |

| Ubuninzi (g/cm³) | 8.3 | 8.4 |

| Iqondo lomlinganiso we Br(%/℃) | -0.05 | -0.035 |

| Iqondo lomlinganiso we-iHc(%/℃) | -0.3 | -0.2 |

| Amandla okuqina (N/mm) | 400 | 350 |

| Amandla okwaphuka anqamlezayo (N/mm) | 150-180 | 130-150 |

Isicelo

Imagnethi ye-SmCo isetyenziswa kakhulu kwi-aerospace, i-motor ephezulu yokumelana nobushushu, izixhobo ze-microwave, unxibelelwano, izixhobo zonyango, izixhobo kunye neemitha, izixhobo ezahlukeneyo zokuhambisa imagnethi, izinzwa, iiprosesa zemagneti, iimotor zekhoyili yelizwi njalo njalo.

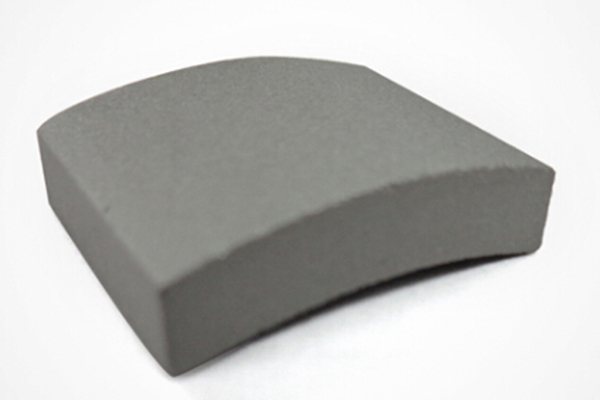

Umboniso Wemifanekiso

-

Ukusebenzisa uMjikelo we-NdFeb kwi-Electroacoustic

-

Phonononga ubungakanani obahlukeneyo beeMaginethi zeFerrite ezibotshelelweyo

-

Icandelo leNdFeB Magnets kwiiMoto zoMbane: Phezulu ...

-

Factory Xabiso For Half Ring NdFeB Strong Magnet...

-

Abathengisi behoyilesi yeSampuli yasimahla ye-N52 Block Neod...

-

Ukhetho olukhulu lweMagnet yeNeodymium enamandla...